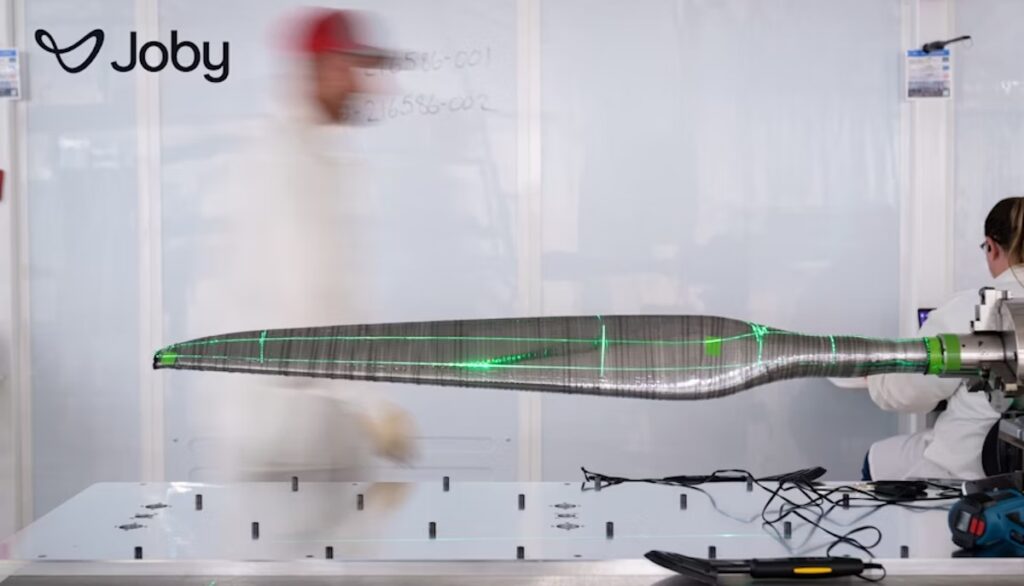

Joby Aviation, a company developing electric air taxis for commercial passenger service, has begun manufacturing propeller blades at its facility in Dayton, Ohio.

This milestone expands in-house manufacturing of a critical conforming component and builds on work already underway in Ohio, including testing, underscoring Dayton’s historic role in aircraft production ahead of the company’s commercial launch.

Joby’s propeller blades are designed for quiet flight and require complex carbon manufacturing processes and a highly skilled workforce, both of which are available in Dayton. With fives blades per propeller and 30 per aircraft, the facility’s production capacity could reach up to 15,000 blades per year as part of Joby’s scaling plan in Ohio. The company expects to complete conforming blades, those meeting all requirements for Federal Aviation Administration (FAA) inspection and certification, next month, with installation on flight test aircraft targeted for next year. The Dayton footprint is expected to eventually support the production of up to 500 aircraft annually, positioning the facility as a strategic site for the mass production of aircraft components.

Eric Allison, Chief Product Officer at Joby, said, “Dayton gives us the resources, talent, and speed to scale one of the most technically demanding parts of our aircraft. Joby’s propeller blades are a key part of what makes our aircraft special, central to its low acoustic profile and the result of a decade of complex engineering.”

Joby selected Dayton for its strong heritage of aerospace and advanced manufacturing, highly skilled local workforce, and close proximity to critical suppliers. Nearly every component needed for blade production is available within a 30-minute radius of the site, providing a foundation for efficient, high-quality manufacturing at scale.

J.P. Nauseef, JobsOhio President and CEO, noted, “Together with our partners at the Dayton Development Coalition and the DeWine-Tressel Administration, we are proud to welcome Joby’s Aviation decision to establish Dayton as its blade production hub, building on its major aircraft manufacturing commitment announced in 2023. This new investment underscores Joby’s confidence in Ohio’s aviation legacy, innovative talent, and advanced manufacturing strength, and reinforces Ohio’s role in shaping the future of flight.”

This work will support Joby’s type and production certification programs and provide capacity for future operational growth. The company is applying manufacturing process learnings, initially developed and refined in California with Toyota, to scale production in Ohio. Dayton is anticipated to become the long-term hub for blade production, backed by the space, resources, and talent needed to meet growing demand. This expansion reinforces Joby’s integrated manufacturing strategy, linking operations in California and Ohio to prepare for commercial service at scale.

To mark the start of production, Joby will host an event at the Dayton facility November 10th, bringing together local leaders, partners, and team members to commemorate the site’s opening and highlight the region’s role in advancing the next generation of aviation.