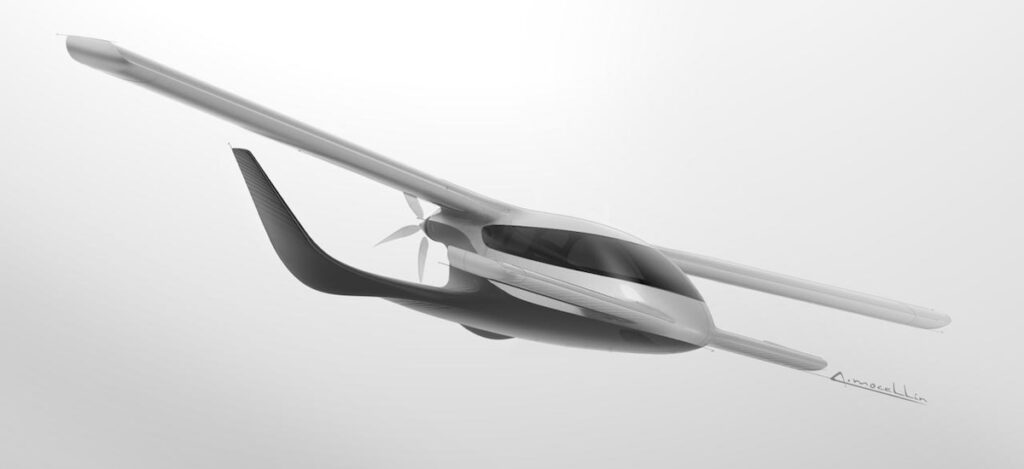

Samson Sky, producers of the Switchblade Flying Car, has completed five years of research and rigorous testing, which has validated the environmentally friendly thermoplastic carbon composite materials and manufacturing techniques they will be using in production of the Switchblade Flying Car.

According to company officials, thermoplastic carbon composites are recyclable and non-toxic, and have a low impact on the environment overall, as opposed to epoxy carbon fiber, which creates waste in the manufacturing process and is difficult to recycle. With thermoplastic carbon fiber, any trimming or waste is recycled immediately into non-structural parts to effectively eliminate waste in the manufacturing process.

Sam Bousfield, Samson Sky CEO and designer of the Switchblade, said; “Composites, which are light weight and extremely strong, have been widely used for decades in high-performance vehicles, such as racecars.”

Bousfield added; “Large manufacturers such as Boeing and Airbus have been using thermoplastic composites in their aircraft for over eight years. Over the past five years of our research and testing, we found an advanced carbon composites material that could be used for the primary structures of the Switchblade.”

Bousfield added that the composites team thoroughly tested the materials numerous ways, and at different temperatures, and is confident in using the material for the all-composite Switchblade vehicle.

Steve McGinnis, Samson Sky composites consultant, said; “This will allow Samson to make the parts eight times faster and at half the cost of anyone else.”

Company officials stated that due to these advances in automated parts manufacturing of thermoplastic carbon fiber, the production of Switchblades will be greatly streamlined, reducing both production costs and time considerably. “Using this automated manufacturing system gives us a large advantage in scaling our production. The volume of orders we already have easily justifies the expense of the more costly machines and molds for the system,” said Bousfield. “With more than 2,700 Reservations and growing daily, Samson is raising the bar for production of carbon fiber vehicles and doing our part to take care of the planet that we all live on.”