Electra.aero has chosen Honeywell flight control computers and electromechanical actuation systems for its nine-passenger hybrid eSTOL aircraft.

These critical technologies will support the fixed-wing eSTOL aircraft’s ability to fly safely and efficiently, helping advance the future of more sustainable and affordable regional air travel. Additionally, Honeywell has made a strategic financial investment in Electra.

JP Stewart, Electra Vice President and General Manager, said; “Honeywell brings deep expertise in control system design, development and certification to support Electra’s goal of creating sustainable, efficient and accessible air travel.

“Honeywell Aerospace Technologies has seamlessly integrated best-in-class and mature flight control technologies, which we believe will be a game changer for making safer, more affordable and sustainable aircraft, ultimately enabling air travel without the airports.”

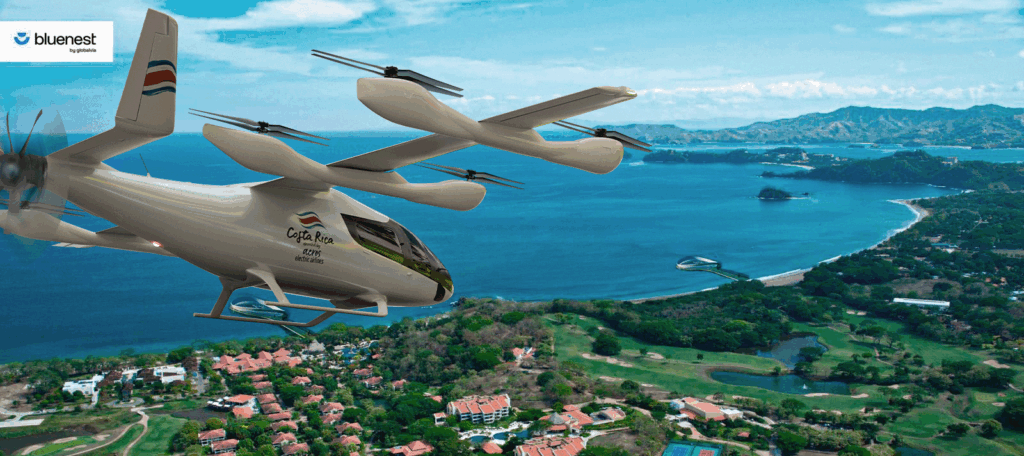

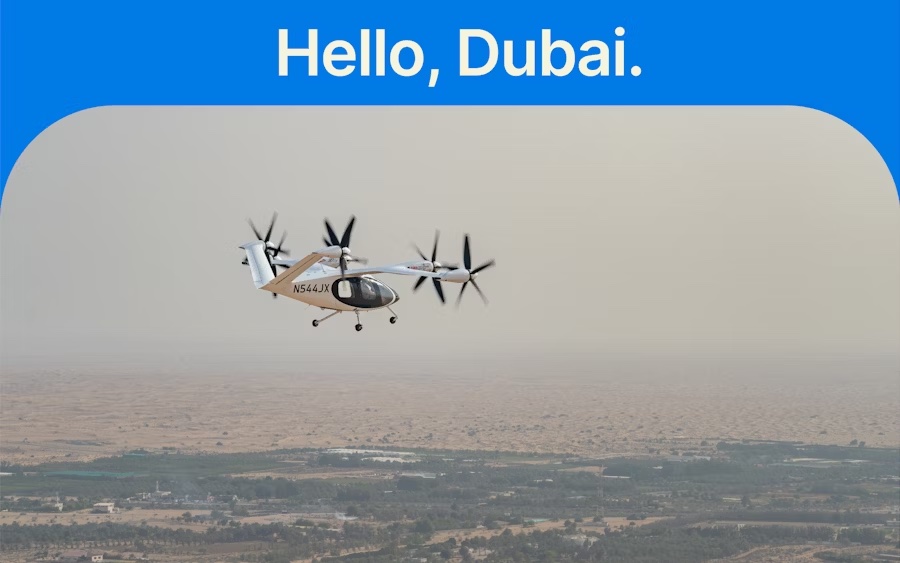

Electra’s eSTOL aircraft combines blown lift technology with distributed electric propulsion, using battery packs and a turbogenerator to power eight electric motors placed along the wing’s leading edge. This allows the aircraft to take off and land in under 150 feet, enabling flight operations from underserved and remote areas using unconventional locations like converted parking lots, barges and short fields. The innovative design achieves 40% lower fuel consumption, significantly reducing operating costs, emissions and noise for community-friendly operations.

David Shilliday, Vice President, Advanced Air Mobility, Honeywell Aerospace Technologies, said; “Electra’s aircraft is perfectly suited to regional air mobility and will enable new access to grow this market.

“Our ability to pre-integrate multiple subsystems will not only help reduce the time it takes to install and integrate these technologies, but it will also enable Electra to expedite and streamline production of its groundbreaking eSTOL aircraft.”

Honeywell’s compact fly-by-wire (cFBW) flight control computers are augmented by electronics, rather than manual controls. The computer or “brains” of the aircraft’s flight controls is about the size of a paperback book, compared with traditional technologies on larger aircraft that are roughly the size and weight of a loaded suitcase. Honeywell’s cFBW computer draws less power, helps reduce turbulence, and can dynamically adjust flight motors to enable smooth flight paths, eliminating the need for heavy hydraulics and control cables.

Honeywell’s electromechanical actuation systems — which convert electricity into mechanical force — allow for safe and efficient flight by taking commands from the pilot or onboard flight management system. Honeywell actuators, which enable actions like moving the flaps on the wing, are smaller, lighter, more reliable and have 10% greater power density than most aerospace actuators available today.

Together, the compact size and lighter weight of both the cFBW flight control computers and electromechanical actuation systems are critical components for Electra’s eSTOL production aircraft.