Electric aerospace company BETA Technologies is building an electric transportation system that includes net-zero, all-electric aircraft and a cross-country, multimodal charging infrastructure to support various types of EVs.

The company has contracted German company Volz Servos as actuator partner for the ALIA supply chain. The leading manufacturer and supplier of electromechanical rotary actuators has provided BETA Technologies with servos for prototyping for the past several years.

The partnership is part of BETA’s strategic approach to its supply chain, including partnering with aerospace leaders on various systems and components for its aircraft production.

BETA undertook an extensive process to identify partners willing to join its mission to deliver its electric aviation system to customers. Many of the engaged suppliers have been partners of BETA’s, working to co-engineer bespoke systems for the Company’s aircraft.

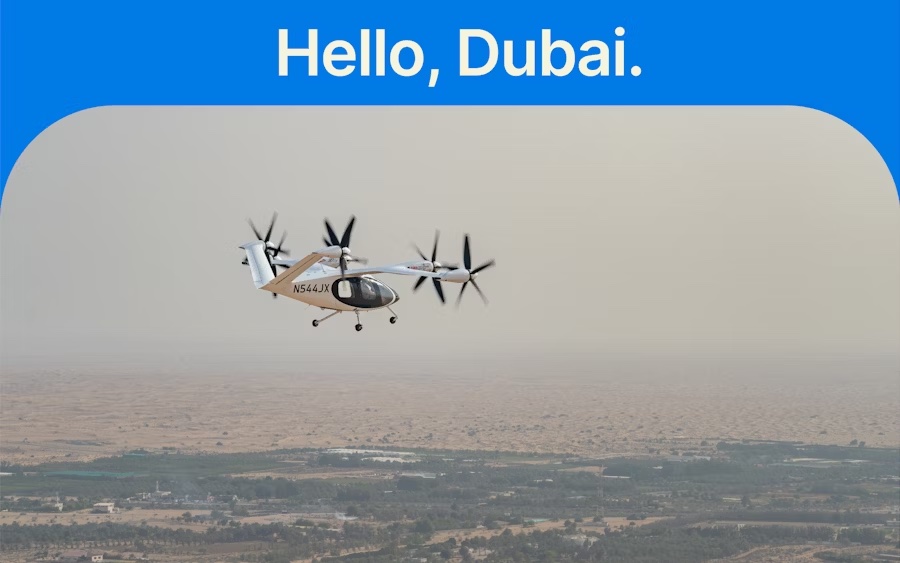

In fact, various partners have supplied systems that are currently installed on the Company’s two test aircrafts and simulators, logging real, practical hours of in-field use and telemetry data.

BETA Technologies Founder and CEO, Kyle Clark commented; “As we continue to progress toward commercialization, it’s been crucial to find partners like Volz who have deep experience and expertise not only in the technology at hand, but in certification too. In addition to providing top of the line actuators that deliver on safety and reliability, Volz has an established record of complying with multiple certification standards.”

With its EASA certified subsidiary AEE (Aircraft Electronic Engineering GmbH), Volz is able to develop, produce and maintain actuators according to the applicable aviation certifications and standards for each domain.

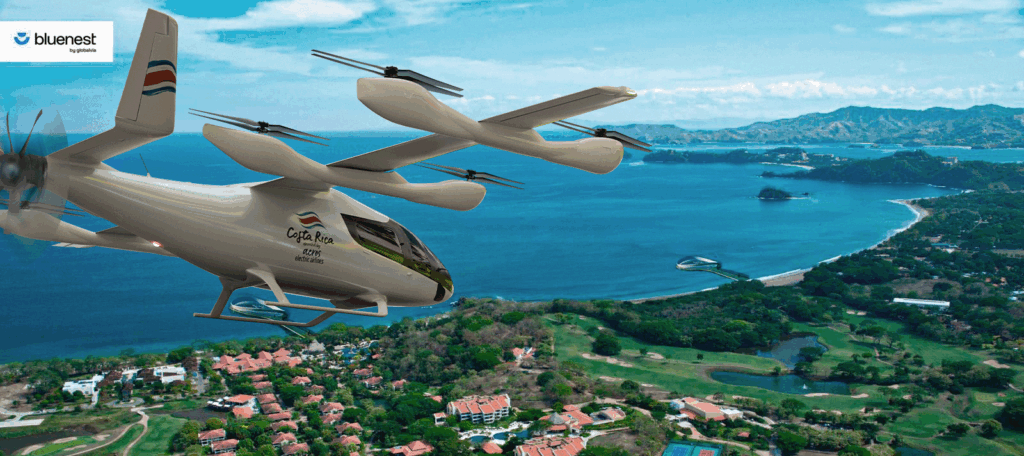

“With the ALIA CTOL and ALIA VTOL, BETA has the most promising projects in uncrewed aviation”, said Phillipp Volz, CEO of Volz Servos, “We are honored by BETA’s trust and are immensely proud to be able to equip these aircrafts with our actuators – especially considering the challenges that eVTOLs still have to overcome today, first and foremost compliance with certification standards. Being able to deliver unique, certifiable actuators that comply with both European and U.S. aviation regulations is crucial for gaining a foothold in a market whose great potential is increasingly being recognized.”